Natural wood is prone to decay from fungal rot or decay, mold, sapstain, or wood-destroying insects. Antimicrobial preservatives are chemicals used to treat wood, helping prevent decay and ensure wood lasts longer, especially wood used outdoors. Fresh lumber is typically treated with wood-preserving chemistries, such as copper-based compounds or borates, before being used in construction or manufactured into new wood products. By helping wood last longer, wood preservatives help reduce the need to replace wood products, lowering the burden on forests and promoting sustainability. Like all other antimicrobial products, wood preservatives are evaluated and registered by the U.S. EPA before their use to help ensure no unreasonable risks to human health or the environment.

Applications Across Wood-Based Industries & Products

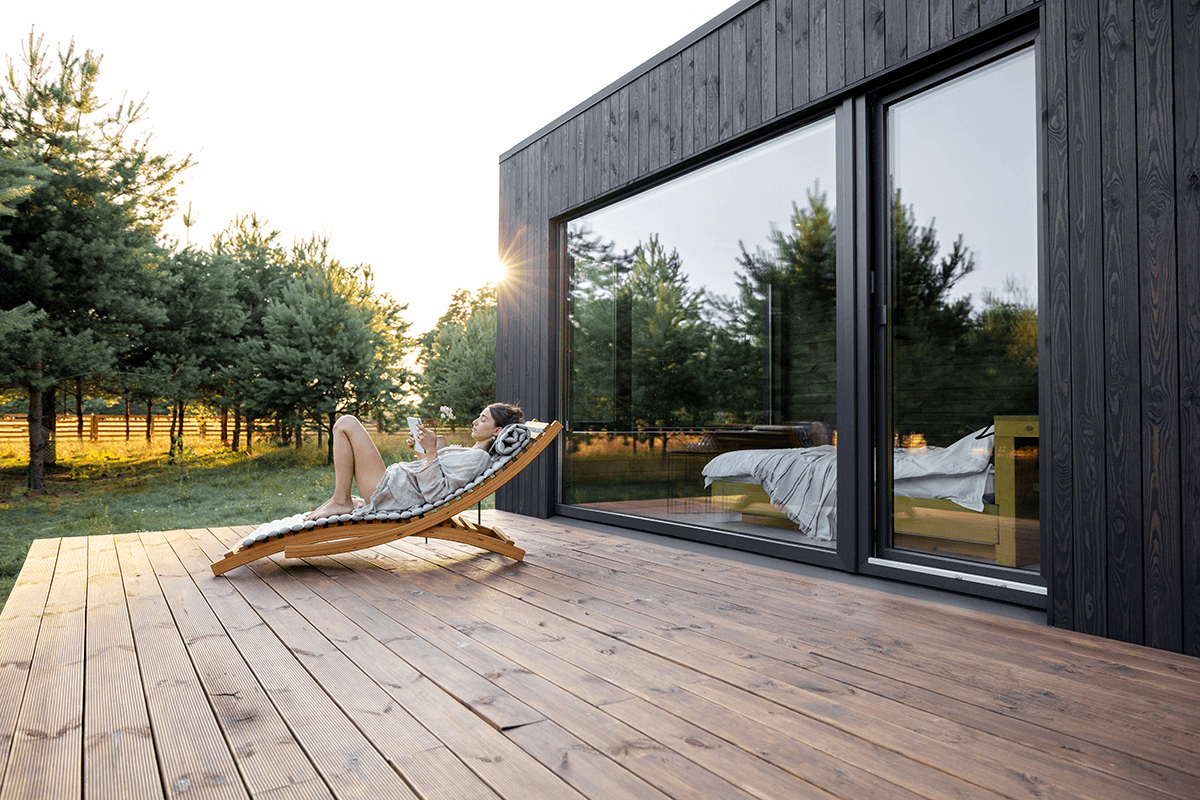

Homes & Furnishings

Treated wood is an essential material for various components of our homes and properties, including house and window frames, decks, chairs, picnic tables, and fencing. Treated wood helps resist decay, helping homeowners avoid costly replacements.

Docks & Marinas

Treated wood is commonly used to build piers, docks, and marina structures. The marine environment is harsh, and wood is susceptible to marine borers, insects, and fungal decay. In such an open environment, untreated wood will last only a few years, but treatment can extend wood’s life significantly.

Railroads

More than 150,000 miles of railway tracks in the United States are bound with wooden railroad ties. In fact, more than 90 to 93% of railroad ties are wooden ties because wood provides the natural flexibility that is needed for railroad function. Ties treated with wood preservatives can remain functional and in use for over 50 years compared to untreated wooden ties that last five years or less.

Utility Poles

Utility poles made from treated wood allow poles to stand up to harsh weather conditions, insects, fungi, and other destructive elements. Wooden poles have a lower carbon footprint during production and lower cost than other materials. Wood preservatives help extend the lifespan of utility poles, reducing replacement frequency and promoting the overall sustainability of choosing wooden utility poles.

Antimicrobial Benefits to Economic & Environmental Sustainability

Extends life cycle of lumber materials

Helps products remain productive for a longer duration

Reduces need for unnecessary manufacturing

Decreases consumption of timber resources

Reduces safety risks of products collapsing or breaking